Laser Safety Program

The purpose of this program is to provide safety procedures for the use of all lasers on campus whether in the classroom or lab. Basic rules will be laid out and explained, as well as an identification of required postings based on class of laser.

The standards described in 21 CFR 1040.10 and 1040.11 will be used as guidelines for this program. This program is also based on ANSI Z136 and the OSHA Technical Manual for Laser Hazards.

Table of Contents

The Authorized User: The person in charge of making sure all safety procedures are followed. This person may be a faculty member whom uses the laser or laser system in their lab, but also can be the faculty member instructing a lab in the case of a laser being used in the classroom. The Authorized User needs to be aware of all safety requirements and procedures and enforce them as needed.

Maximum Permissible Exposure (MPE): The level of laser radiation to which a person may be exposed without hazardous effect or adverse biological changes in the eye or skin. Discussed in the section titled “Laser Exposure Limits”.

Nominal Hazard Zone (NHZ): The Nominal Hazard Zone describes the space within which the level of the direct, reflected or scattered radiation during normal operation exceeds the applicable Maximum Permissible Exposure (MPE). Exposure levels beyond the boundary of the NHZ are below the appropriate MPE level.

Laser Controlled Area: Any locale where the activity of those within are subject to control and supervision for the purpose of laser radiation hazard protection.

CW: Continuous wave laser as opposed to a pulsed laser.

Accessible Exposure Limit (AEL): The maximum accessible emission level permitted within a particular laser class.

Standard Operating Procedure (SOP): A set of operating instructions for a particular laser or laser system. The procedure specifies measures that will ensure safe and correct use of the laser or laser system.

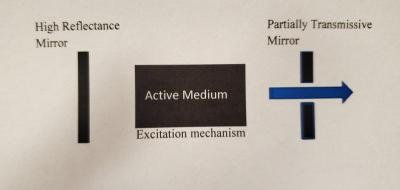

The term Laser is an acronym for Light Amplification by the Stimulated Emission of Radiation. A laser consists of a tube with a medium inside and a mirror at each end of the tube. One mirror is highly reflective, while the other is partially transmissive. As energy excites the medium, the electrons in the medium will jump to a higher energy level. Upon returning to their ground state, they will emit a certain wavelength of light characteristic to this energy level. Some of these light emissions will pass through the partially transmissive mirror in the form of a beam. Other emissions will “bounce” back and forth between the mirrors becoming more intense and eventually continuing on as the beam. This process will continue as long as there is energy applied to the medium. The radiation from a laser may come from the visible portion of the electromagnetic spectrum (400-700 nm wavelengths), invisible infrared (700nm to 3 x 106 nm wavelength), or the ultraviolet region (180-400 nm wavelength). Laser beams emit energy which can be transmitted, absorbed, or reflected on a material.

ABSORPTION

Absorbed laser energy on a material will take the form of heat. Absorption and transmission are physical and chemical characteristics of the material and depend upon the wavelength of the incident radiation. At visible wavelengths, laser radiation striking the eye is focused on the retina, and if sufficient energy is absorbed, it can cause cell destruction and vision impairment. At longer and shorter wavelengths, such as the far infrared and ultraviolet, radiation striking the eye is absorbed in the cornea and the lens. These structures are less susceptible to damage than the cornea but excessive energy absorption may still cause vision impairment.

REFLECTION

Reflection is a function of the physical character of the surface of the target materials. A smooth, polished surface is a good reflector; a rough uneven surface is usually a poor reflector and will produce a diffused reflection. A reflector can change the direction of an incident beam with little or no absorption. This change in direction will depend upon how smooth the surface is and if the surface is flat or curved. If it is a rough, uneven surface, the scattered light will be reduced in energy or power density. These are favorable when designing a laser experiment since they reduce the likelihood of a specular reflection, thus improving the safety of the experiment. The fewer the reflections taking place, the less the likelihood of a laser being reflection into a person’s eye

TRANSMISSION

Most visible light beams, such as those generated by HeNe, Nd:Yag, and Krypton lasers, are transmitted through clear objects. The use of these types of lasers often requires the use of window covers that absorb the beam and prevent the laser hazard from existing outside of the immediate work area. If higher-powered lasers are being used, these coverings must be fire resistant. Some lasers, such as CO2, are not transmitted through glass and do not require the use of window covers.

In order to provide a basis for laser safety requirements, all lasers and laser systems in the United States are classified according to ANSI Z136.1 and the Federal Laser Products Performance Standard (FLPPS). The manufacturer is responsible for determining the laser classification. The builder must classify custom-built and modified lasers. ANSI Z136.1 is enforced by the Occupational Safety and Health Administration (OSHA). The Laser Products Performance Standard is enforced by the Centers for Devices and Radiological Health (CDRH), a part of the Food and Drug Administration (FDA). The following section describes classifications for continuous-wave lasers. The same hazard levels also apply to pulsed lasers with pulse duration of less than 0.25 seconds but classification is more complex. See ANSI Z136.1 for details of the classification. Copies can be purchased through the Laser Institute of America (https://www.lia.org/.

CLASS 1 LASERS

Class 1 lasers are low-powered and do not emit hazardous radiation under normal operating conditions because they are completely enclosed and are exempt from any control measures. Examples of this class are laser printers and laser disk players. These lasers may present hazards if the housing is breached for maintenance (See embedded lasers).

Class 1A Lasers

Special designation that is based upon a 1000-second exposure and applies only to lasers that are “not intended for viewing” such as a supermarket scanner. The emission from a class 1A laser does not exceed the Class 1 limit for an emission duration of 1000 seconds.

CLASS 2 LASERS

Class 2 lasers are visible continuous wave (CW) and repetitive-pulse lasers or laser systems which can emit accessible radiant energy exceeding the appropriate Class 1. Accessible Exposure Limit (AEL) but less than 1 mW. Some examples of Class 2 lasers are some visible wave HeNe lasers and some laser pointers. The human eye blink reflex provides adequate protection for Class 2 lasers. However, it is possible to overcome the blink response and stare into the Class 2 laser long enough to damage the eye. These lasers are typically exempt from control measures other than having a protective housing and label.

CLASS 3R LASERS

Class 3a lasers are systems with power levels of 1 to 5 mW that normally would not produce a hazard if viewed for only momentary period with the unaided eye. Some examples are some HeNe lasers and some solid state laser pointers. They can pose severe eye hazards when viewed through optical instruments (e.g., microscopes, binocular, or other collecting optics). Class 3R lasers must be labeled. A warning label shall be placed on or near the laser in a conspicuous location and caution users to avoid staring into the beam or directing the beam toward the eye of individuals.

CLASS 3b CONTINUOUS WAVE LASERS

Class 3b lasers are systems with power levels of 5 mW to 500 mW for continuous wave lasers but cannot emit an average radiant power greater than 500 mW for more than 0.25s or cannot produce a radiant energy greater than 0.125 J (joules) far an exposure lasting less than 0.25s.. These lasers may be considered hazardous under direct and specular reflection viewing but are not considered hazardous under diffuse reflection or fire hazard.

CLASS 3B PULSED LASERS

Class 3B pulsed lasers are visible or near infrared systems with power levels of 5mW to 500mW but cannot emit an average radiant power greater than 500mW for longer than 0.25 s or cannot produce a radiant energy greater than 0.03 J per pulse. The lasers must bear a warning sign against direct exposure to the beam.

Specific control measures covered in Class 3B lasers shall be used in areas where entry by unauthorized personnel can be controlled. In these areas, unauthorized entry is only permissible with the escort by a qualified laser operator who will instruct these individuals on the personal protective equipment that must be worn prior to entry.

CLASS 4 LASERS

Class 4 lasers are systems with power levels greater than 500 mW for continuous wave lasers or greater than 10 J/cm2 for a 0.25 second pulsed laser. These lasers will produce eye, skin, and fire hazards. This includes intra-beam viewing, specular reflections, and diffuse reflections.

Table 1: Laser Classifications--Summary of Hazards

Applies to wavelength ranges

Applies to hazards

Class | UV | VIS | NIR | IR | Direct Ocular | Diffuse Ocular | Fire |

|---|---|---|---|---|---|---|---|

I | X | X | X | X | No | No | No |

IA | -- | X* | -- | -- | Only After 1000 seconds | No | No |

II | -- | X | -- | -- | Only after .25 seconds | No | No |

IIIR | X | X** | X | X | Yes | No | No |

IIIB | X | X | X | X | Yes | Only when laser output is near class IIIB limit of 0.5 Watt | No |

IV | X | X | X | X | Yes | Yes | Yes |

Key: X = indicates class applies in wavelength range

* = class IA applicable to lasers "not" intended for viewing 'Only"

** =CDRH Standard assigns class IIIA to visible wavelengths ONLY. ANSI Z 136.1 assigns Class IIIA to all wavelength ranges.

EMBEDDED LASERS

Embedded lasers are found in laser products with lower class ratings. Examples are laser printers, CD players, and laser welders. These may have Class 3b or Class 4 lasers in their protective and interlocked housings. When the laser system is used as intended, the lower laser class applies. If the system is opened (for service or alignment) and the laser beam is accessible, the requirements for the higher class laser must be implemented.

Beam Hazards

Injuries related to laser beams may occur, but are dependent upon several parameters. Beam damage and threshold levels of these injuries depend upon the wavelength of light, the energy of the beam, divergence, and exposure duration. If the laser is a pulsed laser, the pulse length, repetition frequency, and train characteristics also have to be considered. ANSI Z136.1 establishes Maximum Permissible Exposure (MPE) limits for laser radiation. This must be determined for each laser so that a Nominal Hazard Zone (NHZ) can be established. The Nominal Hazard Zone is the area around a laser in which the applicable MPE is exceeded. When an MPE is exceeded, damage can occur to the skin, retina, lens, cornea, and conjunctival tissue surrounding the eye. For lasers over 500 mW, the beam can also ignite flammable materials and initiate a fire.

Damage to the eye occurs as the laser enters the eye and is focused on the retina. Normal focusing of the eye amplifies the irradiance by approximately 100,000; thus, a beam of 1 mW/cm2 results in an exposure of 100 W/cm2 to the retina. This can translate into thermal burn, acoustic damage, and photochemical damage to the retina if the laser is in the near ultraviolet (UV), visible, and near infrared (IR) regions (below 400 nm – 1400 nm). The most likely effect is thermal burn since the energy from the laser beam is absorbed by tissue in the form of heat. Retinal tissue does not regenerate; the damage is permanent, which may result in the loss of sight in the damaged area.

For high-powered lasers, a skin hazard may exist. While they are less important than eye hazards, the chance of UV radiation must be considered. This can cause hyperpigmentation and erythema for UV-A. Exposure in the UV-B range can cause the most serious injuries to skin, including potential carcinogenic effects. Exposure to UV-C is the most hazardous and can cause erythema (red/inflamed skin) and skin cancer. Please keep in mind the purpose of the laser. If it is used for welding or cutting hard materials, extreme caution must be taken.

TABLE I: SUMMARY OF BASIC BIOLOGICAL EFFECTS OF LIGHT

Photological spectral domain | Eye effects | Skin effects |

|---|---|---|

| Ultraviolet C (0.200-0.280 μm) | Photokeratitis | Erythema (sunburn) Skin cancer |

| Ultraviolet B (0.280-315 μm) | Photokeratitis | Accelerated skin aging. Increased pigmentation |

| Ultraviolet A (0.315-0.400 μm) | Photochemical UV cataract | Pigment darkening Skin burn |

| Visible (0.400-0.780 μm) | Photochemical and thermal retinal injury | Photosensitive Reactions Skin burn |

| Infrared A (0.780-1.400 μm) | Cataract, retinal burns | Skin burn |

| Infrared B (1.400-3.00 μm) | Corneal burn Aqueous flare IR cataract | Skin burn |

| Infrared C (3.00-1000 μm) | Corneal burn only | Skin burn |

Nonbeam Laser Hazards

The following general safety and health guidelines should be considered in certain laser operations, especially in the research laboratory.

Industrial Hygiene. Compressed gases, cryogenic materials, toxic and carcinogenic materials, and noise should be considered as potential hazards while lasers are in use. Adequate ventilation must be installed to reduce potentially noxious or hazardous fumes and vapors, produced by laser welding, cutting and other target interactions, to levels below the appropriate threshold limit values, e.g., American Conference of Governmental Industrial Hygienists (ACGIH) threshold limit values (TLV’S) or Occupational Safety and Health Administrations’ (OSHA) permissible exposure limits (PEL’s).

Explosion Hazards. High-pressure arc lamps and filament lamps or laser welding equipment shall be enclosed in housings which can withstand the maximum pressures resulting from lamp explosion or disintegration. The laser target and elements of the optical train which may shatter during laser operation shall be enclosed.

Nonbeam Optical Radiation Hazards. This relates to optical beam hazards other than laser beam hazards. Ultraviolet radiation emitted from laser discharge tubes, pumping lamps, and laser welding plasmas shall be suitably shielded to reduce exposure to levels below the ANSI Z136.1 (extended source), OSHA PELs, and/or ACGIH TLVs.

Collateral Radiation. Radiation, other than laser radiation, associated with the operation of a laser or laser system, e.g. radio frequency (RF) energy associated with some plasma tubes, x-ray emission associated with the high voltage power supplies used with excimer lasers, shall be maintained below the applicable protection guides, The appropriate protection guide for RF and microwave energy is that given in the American National Standard “Safety levels with respect to human exposure to radio frequency electromagnetic fields, 300 kHz to 100 KHz,” ANSI C95.1; the appropriate protection guides for exposure to X-ray emission is found in the Department of Labor Occupational Safety and Health Standards, 29 CFR Part 1910.1096 and the applicable State Codes. Lasers and laser systems that, by design, would be expected to generate appreciable levels of collateral radiation, should be monitored.

Electrical Hazards. The intended application of the laser equipment determines the method of electrical installation and connection to the power supply circuit (for example, conduit versus flexible cord). All equipment shall be installed in accordance with the National Electrical Code and Occupational Safety and Health Act. [Additional specific recommendations can be found in Section 7.4 of ANSI Z 136.1 (1993)].

Flammability of Laser Beam Enclosures. Enclosure of Class IV laser beams and terminations of some focused Class 3b lasers, can result in potential fires hazards if the enclosure materials are exposed to irradiances exceeding 10 W/cm2. Plastic materials are not precluded as enclosure material, but their use and potential for flammability and toxic fume release following direct exposure should be considered. Flame-resistant materials and commercially available products specifically designed for laser enclosures should also be considered.

There are four different types of controls that are recommended in ANSI Z136.1. These are engineering controls, personal protective equipment, administrative and procedural controls, and special controls.

These will vary depending upon which class of laser is being used. Because Class 4 lasers are more powerful, there are special controls set for the usage of these lasers which need to be used in addition to the other laser controls.

ENGINEERING CONTROLS

Engineering controls are normally designed and built into the laser equipment to provide safety. These will be provided by the manufacturer of the laser as part of the “performance requirements” mandated by the FLPPS.

- Protective Housing: A laser shall have an enclosure around it that limits access to the laser beam or radiation at or below the applicable MPE level. This is required for all classes of lasers.

- Master Switch Control: All Class 4 lasers and laser systems require a master switch control. The switch can be operated by a key or computer code. When disabled, the laser cannot be operated. Only authorized system operators are to be permitted access to the key or code. A master switch control is recommended but not required for Class 3b.

- Optical Viewing System Safety: When viewing the beam or beam reflection area with an optical viewing system (such as a telescope, microscope, viewing port, or screen), interlocks, filters, or attenuators are to be incorporated in conjunction with beam shutters. These are required for all except Class 1 lasers.

- Beam Stop or Attenuator: Class 4 lasers require a permanently attached beam stop or attenuator which can reduce the output emission to a level at or below the appropriate MPE level when the laser system is on “standby.” This is also recommended for Class 3a and Class 3b lasers.

- Laser Activation Warning System: An audible tone or bell and/or visual warning (such as a flashing light) is recommended as an area control for Class 3b laser operations and is mandatory for Class 4 lasers. Such warning devices are to be activated upon system start-up and are to be uniquely identified with the laser operation. Verbal “countdown” commands are an acceptable audible warning and should be a part of the Standard Operating Procedure (SOP).

- Service Access Panels: ANSI Z136.1 requires that any portion of the protective housing that permits direct access to an embedded Class 3b or Class 4 laser (intended for removal only by service personnel) must have either an interlock or require a tool in the removal process. If an interlock is used and is deflatable, a warning label indicating this fact is required on the housing near the interlock. The design shall not allow replacement of a removed panel with the interlock in the defeat condition.

- Protective Housing Interlock Requirements:

- Interlocks, which cause beam termination or reduction of the beam to MPE levels, must be provided on all panels intended to be opened during operation and maintenance of all Class 3a, Class 3b, and Class 4 lasers. The interlocks are typically electrically connected to a beam shutter. The removal or displacement of the panel closes the shutter and eliminates the possibility of hazardous exposures.

- Under the requirements of ANSI Z136, for embedded Class 3b and Class 4 lasers only, the interlocks are to be fail-safe. Dual, redundant, electrical series-connected interlocks must be associated with each removable panel. Adjustments or procedures during service on the laser shall not cause the safety interlocks to become inoperative or the laser radiation outside a Class 1 laser protective housing to exceed the MPE limits, unless a temporary laser-controlled area is established.

- Remote Interlock Connector: All Class 4 lasers or laser systems must have a remote interlock connector to allow electrical connections to an emergency master disconnect (panic button) interlock or to room, door, or fixture interlocks. When open circuited, the interlock shall cause the accessible laser radiation to be maintained below the appropriate MPE level. This is also recommended for Class 3b lasers.

ADMINISTRATIVE AND PROCEDURAL CONTROLS

- Standard Operating Procedure (SOP): ANSI Z136.1 requires an SOP for Class 4 lasers and recommends one for Class 3b lasers. These procedures need to be written for the specific use of each laser for the purpose intended and safety procedure for the laser.

- Alignment Procedures: A written SOP is recommended for all recurring alignment tasks due to the fact that many eye accidents occur during the alignment process. Use extreme caution while aligning a laser.

- Limitations on Spectators: Only personnel who are necessary for the operation of the laser should be present while it is in use. Unnecessary personnel should not be allowed near the laser during it operation. For the persons whom are necessary, the proper eye protection and instruction is required for class 3b and Class 4 lasers.

- Protective Equipment: For laser safety, in general, the protective equipment is goggles for eye protection, clothing, and any other barriers designed to keep the laser confined to the research area.

Laser Protective Eyewear and Clothing

- Eyewear: Eye protection is designed to protect against radiation from a laser system whenever the levels of accessible emission exceed the appropriate MPE levels (i.e. when engineering controls are inadequate to eliminate the possible hazardous exposure). Eye protection is also designed for specific wavelengths. Therefore, the eye wear used will depend upon the wavelength of the laser system along with the class. .All laser eye wear shall be clearly labeled with OD values and wavelengths for which protection is afforded.

- Clothing: Clothing and/or sun-screen will provide protection from laser radiation, especially in the case of ultraviolet laser systems. Gloves made of tightly woven fabric or opaque materials are recommended for hand protection. A laboratory coat can also be used for protection of the arms. For Class 4 lasers, flame resistant materials should be used.

- Other controls: Because of the fact that eyewear may be provided, but not used, other controls may also be introduced for protection. Protective shielding would be an example.

- Barrier: Special barriers designed to withstand direct or diffusely scattered beams may be used for some systems. These will be described with a Barrier Threshold Limit (BTL). The beam will penetrate the barrier only after some specified exposure time, typically 60 seconds. This barrier should be located at a distance from the laser source so that the BTL is not exceeded in the worst-case exposure scenario. These laser barriers exhibit BTL’s ranging from 10 to 350 W/cm2 (current availability) for different laser wavelengths and power levels. It is essential that the barrier itself cannot be made of a combustible material or become consumed by flames as a result of laser exposure.

SPECIAL CONTROLS:

Beam Path Controls: Some uses of Class 3b and Class 4 lasers require that the beam path is completely enclosed, while other uses required a limited enclosure. In some situations, lasers may require a totally open beam path. Each has its own set of required controls.

- Enclosed (Total) Beam Path

- The most common enclosed (embedded) high-powered laser is the Class 1 laser. It is surrounded by a protective enclosure with interlocks and/or labels on all removable panels and access doors. Thus, during operation, beam access is prevented

- This completely enclosed system, with all appropriate labels and safeguards, fulfills all requirements for a Class 1 laser and can be operated with no additional controls.

- NOTE: During periods of service or maintenance, controls appropriate to the class of the embedded laser are required. This is because when the enclosure is removed, beam access is possible. Beam access during maintenance or while servicing will not alter the Class 1 status of the laser during operation.

- Limited Open Beam Path

- In some cases, an enclosure is built that completely surrounds the optics and the immediate area of the workstation. Often times, there is a computer-controlled positioning table inside this enclosure. This design often allows a gap of less than one quarter of an inch between the bottom of the enclosure and the top of the material to be laser processed. It enables the part to be laser cut or welded to move while the laser optics remain stationary.

- The system may not meet the “human access” requirements for a Class 1 laser, but the real laser hazards are confined. This design is considered a Limited Open Beam Path. A laser hazard analysis need be performed by an authorized user to establish the extent of the NHZ.

- In many of these types of systems, the NHZ will be limited, and procedural controls will be sufficient to ensure safe use. In many cases, the laser unit may be reclassified as a Class 1 laser under the specifications of the ANSI Z136

- A detailed standard operating procedure (SOP) is required along with training for anyone who will be operating the equipment. The SOPs must take into consideration of the class of the embedded laser.

- PPE is recommended only if the hazard analysis indicates a need or if the SOP requires periods of beam access, such as during setup or maintenance activities. Temporary protective measures for service can be handled similarly to the service of any embedded Class 4 laser.

3. Totally Unenclosed Beam Path: For applications where high-power Class 3b and Class 4 lasers are used in an unenclosed beam condition, the authorized user will have to do a hazard analysis and NHZ assessment. Controls need to be chosen to reflect the magnitude of hazards associated with the accessible beam. Some examples are: open industrial processing systems, laser research laboratory installations, and surgical installations.

A laser-controlled area is required when the entire beam path from a Class 3b or Class 4 laser is not sufficiently enclosed and/or baffled so that radiation exposure does not exceed the MPE. During periods of service, a controlled area may be established on a temporary basis. The controlled area will encompass the NHZ. The required controls are as follows:

- Posting with Appropriate Laser Warning Signs:

- Class 3a (beam irradiance of 2.5mW/cm2, Class 3b, and Class 4 lasers require the ANSI DANGER sign format (white background, red laser symbol with black outline and black lettering). This posting is required for Class 3b and Class 4

- Class 2 or Class 3a areas: All signs and labels associated with these lasers for a beam irradiance that does not exceed 2.5 mW/cm2. Use the ANSI CAUTION format (yellow background, black symbol and letters).

- For a temporary laser-controlled area is established, an ANSI NOTICE format is required (white background, red laser symbol with blue field and black lettering). This sign is posted only during the time that a laser is in service.

- Operated by Qualified and Authorized Personnel:

- Training of individuals in laser safety is required for Class 3b and Class 4 laser installations.

- Transmission from Indoor Controlled Area:

- The beams shall not, under any circumstances, be transmitted from an indoor laser-controlled area unless for specific purposes (such as testing). In such cases, the operator and the authorized user must ensure that the beam path is limited to controlled airspace.

TEMPORARY LASER-CONTROLLED AREA

In the case that overriding interlocks becomes necessary, a temporary laser-controlled area shall be devised following specific procedures approved by the Authorized User. These procedures shall outline all safety requirements necessary. All safety requirements must be provided for all personnel in and out of the area during periods of operation.

The following practices are recommended for safe laser use. Depending upon the class of laser and what kind of radiation is being emitted (UV, visible, etc.) additional practices may also apply.

IN THE WORK AREA:

- Isolate lasers from public areas. Close or lock doors to keep unauthorized personnel out. Proper warning signs need to be posted.

- Window shades or covers should be used to keep the Nominal Hazard Zone in the room.

- In order to prevent stray beams, secure the laser to the work surface. This will also prevent lasers from falling and breaking.

- Laser work areas should be kept free of clutter in order to avoid reflections and/or accidental ignition from the laser beam.

- Whenever practical, the laser system or beam should be enclosed to prevent accidental exposure to the beam.

- The area should be as bright as practicable. This will prevent the pupils from fully dilating which can cause more harm to the retina as it will allow more of the beam to enter the eye.

- In order to prevent specular reflections, shield or remove unnecessary reflections.

- It is required that for any accessible laser for which the MPE could be exceeded, the main beam and reflected beams should be terminated or dumped.

- The laser should be set up so that the beam path is above or below normal eye level. This would be the level below 4.5 ft. or above 6.5 feet. Laser work areas should be kept free of clutter in order to avoid reflections and/or accidental ignition from the laser beam.

- Electrical safety standards must be met. An active laser should never be left unattended unless it is in a controlled area.

- For laser with invisible beams, warning devices must be installed to warn when laser is in operation.

LASER USE SAFETY PRACTICES:

- Before operating the laser, warn all personnel and visitors of the potential hazards that exist, and ensure all safety measures area satisfied.

- Clear all personnel from the anticipated path of the beam.

- Wear proper eye protection when working with a Class 3b or Class 4 laser.

- Avoid looking into the primary beam at all times.

- Do not aim the laser with the eye. Direct reflections could cause retinal damage.

- Avoid looking at the pump source.

- Do not wear bright reflective jewelry or other objects.

- Be very cautious around lasers that operate at frequencies not visible to the human eye.

Direct exposure to the eyes should always be avoided, no matter what class of laser is being used. The following will outline requirements for Class 3a, Class 3b, and Class 4 lasers. Some of these are explained in more detail throughout this manual; for more information, see the OSHA Technical Manual or refer to ANSI Z 136.

CLASS 3A:

- Class 3a lasers are only hazardous for intra-beam viewing.

- Limited controls are recommended.

- Protective eyewear is recommended.

- A label that has the laser sunburst symbol and the warning CAUTION for a beam irradiance less than 2.5 mW/cm2.

- A label that has the laser sunburst symbol and warning DANGER for a beam irradiance greater than 2.5 mW/cm2.

- An interlock must be on all panels intended to be opened while the laser is in use.

CLASS 3B:

- For some focused Class 3b lasers, enclosing them can result in potential fire hazards if the enclosure materials are exposed to irradiances exceeding 10 mW/cm2.

- For some Class 3b lasers, plastic materials can cause a toxic fume release if direct exposure occurs.

- In general, Class 3b lasers are not a fire hazard.

- Higher power Class 3b lasers will produce a hazardous diffuse reflection. If a Class 3b laser has an output near the 0.5 Watt limit, there is a possibility of a hazardous diffuse reflection.

- A warning statement of DANGER should be used for Class 3b lasers. It will have a laser sunburst symbol, the type of laser (HeNe, Argon, Co2, etc.), and the power or energy output specified.

- A Nominal Hazard Zone (NHZ) must be specified for a Class 3b laser if the laser radiation (either direct, reflected, or scattered) will exceed the MPE during normal operation.

- Avoid direct exposure to the eyes.

- Training in laser safety is required.

- Any noninvolved personnel entering the room need to be approved by the Authorized User.

- Beam stops of an appropriate material must be used to terminate all potentially hazardous beams.

- Where appropriate, diffusely reflecting material should be used near the beam.

- Laser protective eyewear must be provided for all personnel within the laser controlled area.

- The beam path must be above or below the eye level of any standing or sitting person in the area.

- All windows, doorways, open portals, etc. of an enclosed facility should be covered or restricted to reduce any escaping laser beams below the appropriate ocular MPE level.

- Lasers must be stored or disabled when not in use.

- Standard Operating Procedures are recommended for explaining the administrative and procedural controls. These should include information on the controls being used during maintenance or if the protective housing is removed.

- The protective housing must require the use of a tool or an interlock in order to be

- Interlocks must be provided that cause beam reduction or termination.

CLASS 4:

- PPE is required for Class 4 lasers, this includes eyewear and protective clothing.

- Enclosure materials must be flame-resistant. A potential fire hazard exists with Class 4 lasers.

- Class 4 lasers are hazardous to view under any condition: directly or diffusely Class 4 lasers are a potential skin hazard.

- Warning sign with the laser sunburst symbol and the word DANGER must be posted on the doorway into room where the laser is being used.

- The DANGER sign must have the type of laser (HeNe, CO2, Argon, etc.) and the power or energy output specified on it.

- A Nominal Hazard Zone (NHZ) must be determined by the Authorized User.

- Training of individuals in laser safety is required. Protective eye wear is required.

- The beam shall not, under any circumstances, be transmitted from an indoor laser controlled area unless for specific purposes.

- It is required that direct supervision by an individual knowledgeable in laser safety takes place.

- Entry of any noninvolved personnel requires approval.

- A beam stop of an appropriate material is used to terminate all potentially hazardous beams.

- The use of diffusely reflecting materials near the beam where appropriate.

- The beam path must be located and secured above or below the eye level for any understanding or seating position in the facility.

- All windows, doorways, open portals, etc. of any enclosed facility should be covered or restricted to reduce any escaping laser beams below appropriate ocular MPE level.

- Lasers must be stored or disabled when not in use.

- A written SOP is a requirement.

- All entryways shall allow rapid entrance/exit under any condition.

- The controlled area shall have a clearly marked “Panic Button” that allows rapid deactivation of the laser.

- One of four entryway controls (see Entryway Controls Section) should be in A temporary laser-controlled area is required when doing maintenance or service.

- As with the other classes of lasers, protective housing should be on the laser.

- A Master Switch Control is required for all Class 4 lasers. When disabled, the laser cannot be operated. Enabling/disabling a laser can be done either by a key or a computer code.

- Optical Viewing System Safety is required for all classes of lasers. These are interlocks, filter, or attenuators are to be incorporated in conjunction with beam shutters when optical viewing systems (telescopes, microscopes, view ports, etc.) are being used.

- It is required for Class 4 lasers that there is a beam stop or attenuator that can reduce the output emission to a level at or below the appropriate MPE level when the laser system is on standby.

- An audible sound and/or visual warning such as a flashing light is mandatory for Class 4 lasers. These sound/visuals should be associated with when the laser is in operation. A verbal “countdown” is an acceptable warning system, but must be written in the SOP so that it is followed by all users.

- Service Access Panels must have an interlock or require a tool to be removed. If an interlock is used and is defeatable, a warning label indicating this fact is required on the housing near the interlock.

- Interlocks must be provided on all panels intended to be opened during operation maintenance. These interlocks must be “fail-safe”. Any adjustments or procedures during service cannot cause the interlocks to become inoperative.

- All Class 4 lasers are required to have a remote interlock connector to allow electrical connection to an emergency master disconnect (panic button) interlock to a room, door, or fixture interlocks. When open circuited, the accessible laser radiation is to be maintained below the appropriate MPE level.

These control measures are in addition to the safety measures for Class 4 lasers and laser systems. In brief, the safety measures are as follows:

- All personnel entering the area shall be adequately trained and provided proper laser protective eye wear.

- All personnel must follow all applicable administrative and procedural controls.

- The area shall provide rapid entrance and exit under all conditions.

- A clearly marked “panic button” shall be in the area that allows rapid deactivation of the laser.

There are four options provided by the ANSI Z136 standard for entryway control:

- Nondefeatable Entryway Controls: A nondefeatable control is one option. An example is a magnetic switch that is built into a doorway. It would serve the purpose of shutting off the laser when the door is opened. Training is required for those persons whom regularly work in the laser area.

- Defeatable Entryway Controls: A defeatable control may be temporarily inactive if it is clearly evident that no hazard exists at the point of entry. Training is required. These controls need to be designed to allow rapid entrance/exit by the laser personnel at all times, especially in an emergency situation. A “panic button” which deactivates the laser under emergency situations must be readily available. If there is a circumstance when the beam path is not completely enclosed, access to the laser controlled area shall be limited only to personnel wearing proper PPE. All other optical paths (windows, doors, etc.) shall be covered or restricted to reduce the transmitted intensity of laser radiation to levels at or below MPE for direct irradiation of the eye.

- Procedural Entryway Controls: A blocking barrier, screen, or curtain that can block or filter the laser beam at the entryway may be used inside the controlled area to prevent the laser light from exiting the area at levels above the applicable MPE level. A warning light or sound is required. Personnel must be properly trained.

- Entryway Warning Systems: A laser warning system shall be installed for all Class 4 lasers as described:

- A laser activation warning light assembly shall be installed outside the entrance to each laser room facility containing the Class 4 laser.

- In lieu of a blinking entryway warning, the light assembly may be interfaced to the laser in such a manner that a light will indicate when the laser is NOT operational, and by additional light when the laser is powered up but not operating, and by an additional (flashing) light when the laser is operating.

LASER USE WITHOUT PROTECTIVE HOUSING (ALL CLASSES)

If, during research, it is necessary to have the protective housing removed from the laser, the following must be done for any class of laser:

- The Authorized User must assess the situation, determine the hazards, and ensure safe operation within the MPE levels are followed.

- Access to the laser control area must be restricted.

- Eye protection must be worn.

- Barriers, shrouds, beam stops, etc. must be in place and used so that radiation does not escape.

- Administrative and procedural controls must be followed.

- The users must go through education and training for the specific circumstance.

The FDA and ANSI have set limits for laser exposure. At this institute, we will be following the ANSI standard because it is a “user” standard and provides Maximum Permissible Exposure (MPE) limits.

These limits are derived from biological research studies and refer to a defined limiting aperture, mainly the diameter of a fully dilated human eye pupil, which is 7 mm.

For more information, see ANSI Z 136 or the OSHA Technical manual for Laser Hazards, which can be found on the OSHA website.

Table III. Summary: Maximum Permissible exposure limits*

Wavelength | ------------MPE leve (W/cm2)------------ | ||||

|---|---|---|---|---|---|

| Laser type | (µm) | 0.25 sec | 10 sec | 600 sec | 30,000 sec |

| CO2 (CW) | 10.6 | --- | 100.0 x 10-3 | --- | 100.0 x 10-3 |

| Nd: YAG (CW) | 1.33 | --- | 5.1 x 10-3 | --- | 1.6 x 10-3 |

| Nd YAG (CW) | 1.064 | --- | 5.1 x 10-3 | --- | 1.6 x 10-3 |

| Nd YAG (Q-switched) | 1.064 | --- | 17.0 x 10-6 | --- | 2.3 x 10-6 |

| GaAs (Diode/CW) | 0.84 | --- | 1.9 x 10-3 | --- | 610.0 x 10-6 |

| HeNe (CW) | 0.633 | 2.5 x 10-3 | --- | 293.0 x 10-6 | 17.6 x 10-6 |

| Krypton (CW) | 0.647 0.568 0.53 | 2.5 x 10-3 31.0 x 10-6 16.7 x 10-6 | --- --- --- | 364.0 x 10-6 2.5 x 10-3 2.5 x 10-3 | 28.5 x 10-6 18.6 x 10-6 1.0 x 10-6 |

| Argon (CW) | 0.514 | 2.5 x 10-3 | --- | 16.7 x 10-6 | 1.0 x 10-6 |

| XeFI (Excimer/CW) | 0.351 | --- | --- | --- | 33.3 x 10-6 |

| XeCI (Excimer/) | 0.308 | --- | --- | --- | 1.3 x 10-6 |

* Source: ANSI Z 136.1 (1993)

The information in this table provides the MPE value for different laser operating for different overall exposure times. The times chosen were:

- 0.25 seconds: The human aversion time for bright-light stimuli (blinking). This is the “first line of defense” for unexpected exposure and is the basis of the Class 2 safety rules.

- 10 seconds: This time limit represents the optimum “worst-case” time period of ocular exposure in or near infrared wavelengths.

- 600 seconds: This is the time period chosen to represent the worst-case scenario for viewing visible diffuse reflection during tasks such as alignments.

- 30,000 seconds: This time period represents a full, 8 hour (28,800 seconds) work day rounded off.

NOTE: These MPE are expressed in irradiance terms W/cm2 that would be measured at the cornea. They will vary by wavelength and exposure time.

Repetitively Pulsed Exposures:

The ANSI Z 136 standard requires a decrease in the MPE for scanned or repetitive-pulse radiation in the range of 1000-15000 Hz. Because of the pulsed activity, research has shown less retinal damage for pulsed lasers than for CW lasers. Multiple-pulse (scanning) lasers operating from 1 to 15,000 Hz have a correction to the single pulse MPE. The correction factor is determined by taking the fourth root of the total number of pulses (N) in a pulse train. Therefore calculated such that the MPE radiant exposure or integrated radiance of an individual pulse within the train is reduced by a factor N -1/4 .

Reviewed by Risk/EHS on November 11. 2024