Introduction

Laboratory hoods are designed to protect laboratory personnel by capturing or containing contaminants such as chemical vapors, gases, dusts, mists, fumes, and preventing their escape into the laboratory environment. Hoods provide physical isolation and containment of chemicals and their reactions. A laboratory hood is a ventilated, enclosed workspace capable of capturing, containing and exhausting fumes, vapors, and particulate matter generated inside the enclosure. It consists of side, back and top enclosure panels, a work surface or counter top, access opening called the face, a sash and an exhaust plenum with a baffle system for regulating airflow. Laminar flow cabinets, biological safety cabinets and glove boxes are not laboratory hoods.

The purpose of this program is to provide general information regarding the selection, use, installation, design and performance of local exhaust hoods. Local exhaust hoods in laboratory facilities should comply with the most recent edition of INDUSTRIAL VENTILATION published by the American Conference of Governmental Industrial Hygienists (ACGIH), Uniform Mechanical Code, as well as the applicable American Society of Heating, Refrigeration and Air-Condition Engineers (ASHRAE) standards and Nation Fire Protection Association (NFPA) codes, NFPA 91 and NFPA 45, ANSI/AIHA Z9.5-2003 and the OSHA Laboratory Standard 29 CFR 1910.1450.

Laboratory Ventilation

Chemical Fume Hood Types

- Conventional Fume Hood or constant air volume hood. Equipped with an internal baffle to the exhaust opening. Face velocity is inversely proportional to sash height.

- Bypass Hood is designed so a fraction of air entering the hood face may pass over the top and bottom of the hood sash. This allows the air velocity near the work surface to stay relatively constant. This protects susceptible experiments and equipment from excessive air speeds which could have detrimental effects. It also allows for less static pressure and frictional resistance to air flow than would a conventional hood. This ensures a constant air volume as the hood sash height is changed.

- Auxiliary Hood is a bypass hood with a direct auxiliary air connection that has not been cooled in the summer or completely heated in the winter. This is an attempt to reduce heating and cooling costs for the institution. Its disadvantage is that it increases maintenance costs due to the requirement of more ductwork, fans and air tempering facilities.

- Self-Contained Hoods pull room air over the work surface and through a filter suitable for the work intended in the hood. This prevents the fan from being contaminated because the air has already has been filtered. Such hoods are desirable in areas where ductwork is not available. Filters usually need to be replaced every 1 to 2 years.

- Walk-in Hoods rest directly on the floor or on a pad on the floor. They are designed to fit around an apparatus which will not fit in a standard hood.

- Explosion-proof Hoods have ”explosion-proof” electrical devices. The hood will not contain an explosion but the electrical equipment will not provide a source of ignition.

- Perchloric Acid Hoods are designed for use with perchloric acid and must be equipped with a water wash system for the hood and ductwork.

- Radioisotope Hoods are designed for use with radioactive chemicals and constructed from stainless steel without seams or edges.

- Variable Air Volume (VAV) Hood maintain a constant face velocity regardless of sash position. The system continuously measures the amount of air exhausted to maintain a constant face velocity. A VAV system increases the ability of the hood to protect the worker from the possibility of exposure to chemical fumes.

Specialty Exhaust Systems

- Biological Safety Cabinet is not a laboratory hood and considered to be a special safety enclosure used to handle and contain pathogenic microorganisms. The cabinet is designed to protect the product and also provides limited protection for lab personnel by utilizing an inward airflow away from the employee. Biological Safety Cabinets must be National Sanitation Foundation (NSF Standard 49) certified for Class II, Type A2 Biological Safety Cabinets and bear the NSF seal.

- Laminar Flow Cabinets are not considered laboratory hoods and do not provide any protection for lab personnel and are intended to provide a clean airflow for the product protection. It is typically a ventilated, partially enclosed cabinet with airflow over the work surface.

- Canopy Hoods have an enclosed horizontal duct suspended above a work area that is too large to be contained in a conventional hood. The disadvantage of the hood is it draws contaminants past the workers breathing zone.

- Glove box is used when toxicity, radioactivity or reactivity is too great a hazard for work in a conventional hood. The greatest advantage of the glove box is worker protection.

Laboratory Chemical Fume Hood Practices

Laboratory hoods do not provide absolute containment or personal protection from exposure to hazardous chemicals or materials. The following guidelines describe safe work practices for the use of laboratory hoods.

- Conduct all operations that may generate hazardous air contaminants inside a hood.

- Properly use traps or scrubbers when toxic or noxious vapors are generated.

- Use only materials that are appropriate for the hazard rating of the hood.

- Confirm the exhaust system is operating properly by verifying airflow through the hood.

- Keep hood clean and uncluttered. Wipe up spills immediately.

- Always turn on interior lighting for proper illumination of the work surface.

- Keep all apparatus at least six inches back from the face of the hood.

- Never put your head inside a hood with potential for exposure to hazardous contaminants.

- Hoods should not be utilized as a waste disposal mechanism for volatile materials.

- Do not use hoods for the storage of chemicals or apparatus.

- Place all heat generating equipment in the rear of the hood to minimize the effect of convection currents on airflow.

- The hood sash is designed to be used as a limited safety shield and should be as low as practical. Maintain the hood sash height no higher than 18 inches and no lower than 12 inches unless specified by the manufacturer, authorized the lab supervisor or department head.

- Use an appropriate barricade in front of the hood if there is a chance or explosion or eruption of material. The sash is not an appropriate barrier for these types of reaction.

- Place large apparatus to the rear of the hood and raise it off the surface two to three inches to allow airflow under the object and into the lower rear exhaust opening. Maintain a distance of at least one inch from the rear so as not to block the flow of air into baffles.

- Be aware of occupant traffic and open doors which may interfere with normal hood exhaust.

- Do not place electrical receptacles or other potential electrical spark sources inside the hood when flammable liquids or gases are present. No permanent electrical receptacles are permitted in fume hoods unless approved by the manufacturer.

- Provide adequate maintenance for all hood exhaust systems and building supply air systems.

- Do not block air supply vents or exhausts, and do not remove sash or panels of the fume hood.

- Ensure the sash is closed and the fume hood lights are off when the hood is not in use.

Laboratory Chemical Fume Hood Procedures

Sash Height Stickers

- For hoods not equipped with 18 inch sash stops, the maximum sash height will be identified as shown on the label below for each laboratory hood system. The sash should not be raised above either the sash stop or the maximum sash height, as it will compromise the safety of lab personnel.

- The average face velocity of the hood determines which chemicals may be used in the hood. Chemicals that are flammable, combustible or have lower toxicity may be used in fume hoods with a face velocity of 80-100 fpm (feet per minute) while chemical with higher toxicity should be used in hoods of 100-120 fpm or where outside influences affect hood performance.

- Work practices and make-up air will affect the performance of laboratory hoods. Face velocity should be about 100 fpm at the highest working sash height. Working sash height should be no higher than 18 inches and no lower than 12 inches. Face velocities may be as low as 75 fpm and as high as 150 fpm.

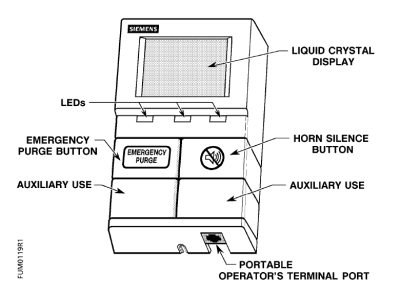

Fume Hood Controllers

- Hood systems in McCollum Science Hall (installed after the year 2000) are equipped with fume hood controllers. The controllers have the following capabilities:

- Digital meter which normally indicates a face velocity of 100 ± 10 fpm of airflow. As the sash is moved up and down on these hoods, the airflow will increase or decrease to maintain a constant face velocity.

- An audible alarm which would indicate either a high or low face velocity. This alarm can be silenced by the mute button on the controller. If the hood continues to alarm, contact EH&S to have the problem investigated and resolved.

- Colored hood status lights indicating normal (green), marginal (yellow), and alarm (red).

- Emergency purge that when pressed will increase the airflow to the hood if a toxic spill or gas release takes place. If the release takes place within the hood, the sash should be closed. If the release is in the lab, the sash should be fully opened. In either case the lab should be evacuated following using the emergency purge function and public safety should be notified.

- Hoods installed between 1990 and 2000 are equipped with fume hood controllers with digital readouts but do not have the audible alarm, colored status lights or emergency purge functions.

- More advanced controllers have been installed in BEG 202 and 302 and MSH 112 and 123. Features consist of::

- Digital display of face velocity in meters per second (mps) or feet per minute (fpm)

- Digital display of exhaust airflow in cubic meters per hour (m3/h), cubic feet per minute (cfm) and liters per second (l/s)

- Green, yellow and red LED status lights

- Alarm horn with dedicated silence alarm button

- Emergency max push button

Table 1. Description of Advanced Controller and Functions

| Visual Indicators | Meaning | Action |

|---|---|---|

| Fume Hood is operating efficiently. | None | |

| Action required | Press Key 5 to return to energy efficient operation, check display for instructions. | |

| Green LED-Solid LED display reads Normal and indicates fume hood velocity | Normal Operation, no alarms or warnings present | None |

| Green LED – Flashing | Pending change to Low air volume flow mode. Fume hood is operating in Low airflow mode, no alarms or warning present.

| Follow lab safety procedures |

| Yellow LED – Solid LED display reads High or Low warning | High airflow warning Low airflow warning. Sash open above maximum operating position Stabilizing jet fan failure. | Follow lab safety procedures for high airflow warning indication. Follow lab safety procedures for low airflow warning indication. Close sash to a safe operating position. Follow lab safety procedures for stabilizing jet fan failure. |

| Yellow LED – Flashing LED display reads High or Low warning | Fume hood use for lab room exceeded. | Close fume hood sash to reduce fume hood exhaust |

| Red LED LED display reads High or Low Alarm LED display then indicates Close sash. | High airflow alarm. Low airflow alarm. Emergency purge Airflow measuring.

| Follow lab safety procedures. Close sash as requested and contact appropriate Facilities Management for repair. |

| LED display reads Failure. LED then indicates Close sash. | Indicates a hood system failure. | Close sash as requested and contact appropriate Facilities Management for repair. |

| Audible information | Meaning | Action |

|---|---|---|

| Constant buzz | High airflow alarm. Low airflow alarm Emergency purge Airflow measuring or sash measuring device failure Fire | Follow lab safety procedures |

| Long buzz | Sash open above maximum operating position | Close sash to safe operating position |

| Short buzz | Pending change to Low air volume flow mode | Follow lab safety procedures |

| Five buzz/minute | Sash opening alert | Close fume hood sash to reduce fume hood exhaust |

| Buttons/Controls | Meaning | Action |

|---|---|---|

| Horn/Silence | Mutes audible alarm | None |

| Emergency MAX LED display reads EMERGENCY | Causes rapid exhaust of fume hood contents in a spill situation | If there is a spill, push button, lower sash, and follow lab safety procedures. Press Emergency MAX again when cause of emergency has ended. |

Baffle Adjustments

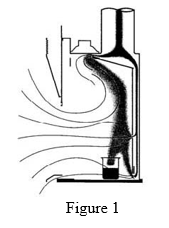

Fisher Hamilton fume hoods have 3 baffle adjustments:

- Normal or Average is for normal exhaust requirements. In most circumstances contaminates generated with a hood mix quickly and have a density nearly the same as air. As shown in figure 1 below this baffle position allows flow in both the lower and upper parts of the hood.

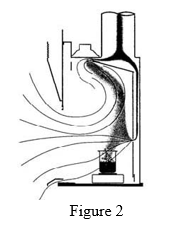

- Lighter than air gases is used for a hot plates or other hot process used inside the hood. As shown if figure 2, this position allows more air flow in the upper part of the hood and will give the best performance for this condition.

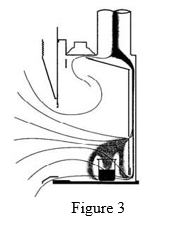

- Heavier than air gases is used for large volumes of dense vapors (such as chlorinated solvents) being generated within the hood. Figure 3 demonstrates this position increases the volume of air being exhausted from the lower part of the hood.

Laboratory Chemical Fume Hood Maintenance

If a fume hood is in need of maintenance such as changing a fluorescent bulb, working on the ventilation or plumbing of the hood, the work must be coordinated at a time for both the convenience of the faculty member and the maintenance staff. This allows the faculty member to properly prepare the hood for the maintenance work and reduces the amount of interference with laboratory classes and research.

Prior to maintenance work on a chemical hood the following steps must be performed:

- All chemical reactions must be shut down.

- Chemicals in the hood must be removed from the hood and properly stored.

- Hood surface must be wiped down and decontaminated.

- Radioactive isotope hoods must be thoroughly wiped down and audited by the Radiation Safety Officer prior to maintenance being performed.

Procedure for Testing Chemical Fume Hoods

An assessment of chemical fume hood operation will be completed upon installation, renovation, when a deficiency is reported or a change has been made to the operating characteristics of the hood. Fume hood tests will be conducted annually by the UNI Risk Management/Environmental Health and Safety Office and will examine face velocity and the containment capability of each hood. An assessment of fume hoods is comprised of two steps.

The first step involves a physical audit of both the inside and outside of the hood. The auditor will be evaluating the hood for the following:

- Use of proper materials designed for that fume hood.

- Excessive storage of any materials inside the fume hood.

- General hood cleanliness.

- Physical damage to the fume hood.

- Ensure lighting is fully functional.

- Sash is broken.

- The ability of the sash to open, close and stay in a stationary position.

- Fume hood monitor is properly functioning.

The second step involves evaluation the performance of the hood.

- Smoke emitter candles will be used to check for turbulence and containment capacity of the hood.

- The average face velocity should be confirmed and used to determine the rating and appropriate use of the hood.

- A sound level meter will be used to check if noise generated by the hood is above 85 dB.

Testing conditions

- All fume hood tests will be performed in rooms where the ventilation has been properly balanced and where supply and exhaust ventilation is in full operation.

- Fume hoods being tested will in the half open or 18” working position.

- Other fume hoods in the room will have their sashes in the half open position during testing.

- Hoods being tested should be empty of unnecessary chemicals and equipment.

- Hood surfaces should be cleaned and decontaminated.

- Radiation hoods must be cleared for testing by the Radiation Safety Officer.

- The doors to the laboratory should be closed.

- When adjustments are made to the sashes the ventilation will be allowed to stabilize before testing is done.

- The hood monitor is calibrated and not in alarm.

Microanometer Instructions

- Ensure meter is fully charged

- Press the ON button on the ADM-880C microanometer.

- Press MODE until the display shows “VELGRID.”

- Press STORE until the display shows “STORE ALL.”

- Place the Velgrid at the fume hood face with the sash half open.

- Press READ and wait for velocity measurement. (One only need press READ for each subsequent velocity measurement)

Determination Method of Average Face Velocity

- Ensure the calibration of the microanometer is current

- The hood face should be divided equally into rectangles of approximately 14” wide each. Perform test in center of each rectangle.

- Record face velocity measurements.

- Average readings to determine the average face velocity. The readings should be between 80-120 fpm (100 fpm) optimum) at the half open position.

- Reading variations should be within ±20% of the average face velocity.

Fume Hood Air Flow Testing Procedure

- Position sash at 18” position.

- Place smoke candle in small metal can at least ¾ filled with sand with candle portion facing up.

- Light candle with lighter or match.

- Place candle within 6” of hood face around the opening of the hood. Smoke should be contained within the hood.

- After candle goes out place in metal or glass container filled with sand labeled “Used Smoke Candles.” Throw candles away no earlier than 24 hours after use.

Sound Level Measurement

- Using a properly calibrated sound meter, ensure sound level is below 85 dB.

- Measurements should be taken at approximately eye level just outside of the hood face.

Conditions Necessary for Passing a Fume Hood Tests

- The physical audit does not reveal conditions or work practices that the assessor deems to be unsafe.

- Average face velocity with the sash at the half open or 18” positions should be between 80-120 fpm. Readings must be no less than 75 fpm or greater than 150 fpm.

- Smoke should be contained within the hood.

- Sound level measurement should be less than 85 dB.

- Upon successful completion of testing the following label will be placed in an obvious location on the hood. The following information should be entered on the label: building and room number, hood designation number, the date the test was performed, the face velocity, the results of the containment test (pass or fail) sound level, sash height, assessor's initials and any necessary comments that need to be passed onto the user or users of the fume hood.

- If a laboratory hood does not pass an annual audit the hood will be labeled with the notice “Fume Hood is Out of Service” as shown in the Appendix. The lab supervisor and department head will be notified of any hood that does not pass the audit. The notice will not be removed until the necessary repair is complete.

University Testing Schedule

Annual chemical fume hood assessments begin the first week of May and and are completed by July 31st of each calendar year. In an effort to reduce interference with ongoing research and classes, departments will be notified at least one week prior to the beginning of the planned audit. If the faculty member does not wish to have his/her hoods assessed during the time planned for their individual hood or hoods, they must contact the Risk Management/Environmental Health and Safety Office to set up a time to have it assessed. If the faculty member fails to notify the EH&S office that he or she does not wish to have the hood audited during the scheduled time, it will be assessed as scheduled.

If a department wishes to be assessed at a specific time during the year, the Environmental Health and Safety Office will work with them so the hoods can be assessed at a time that is convenient for members of the department and auditor.

Reviewed by Lab Safety Committee on March 23, 2022

Reviewed by Risk/EHS on October 21, 2024